A niche choice in the lingerie industry: creating a unique boutique line!

Lycra fabric, a synthetic fiber material, is extremely elastic, yet able to maintain a certain level of softness. At the same time, it also has good abrasion resistance and durability. Therefore, Lycra fabric is widely used in various fabrics that need high elasticity, such as underwear, swimwear, fitness wear, leggings, socks, etc.

Because Lycra fabric can better adapt to different body shapes and sports needs, it is more suitable for the lingerie industry to meet the demand of "small amount of diversified" orders.

01 The 4 major abilities that manufacturers need to have to create a fine line in the lingerie industry

A small number of diversified orders places higher demands on lingerie manufacturers, and how to achieve a "small number of diversified" orders in a boutique line?

- Rapid order response: Manufacturers need to be able to respond to customer orders in the shortest possible time and be able to quickly adjust production lines and supply chains to meet market demand;

- Flexible production capacity: Manufacturers need to have flexible production capacity and be able to quickly adjust production lines and processes to meet different order requirements;

- Intelligent production capacity: manufacturers need to adopt digital manufacturing technologies, such as digital cutting equipment and intelligent sewing machines, in order to improve production efficiency and accuracy and to be able to adapt themselves to the characteristics of different fabrics;

- Supply chain management capabilities: Manufacturers need to have efficient supply chain management capabilities to ensure the timely supply of fabrics and other raw materials, while being able to control inventory and reduce waste rates.

02 How can manufacturers have these kinds of capabilities?

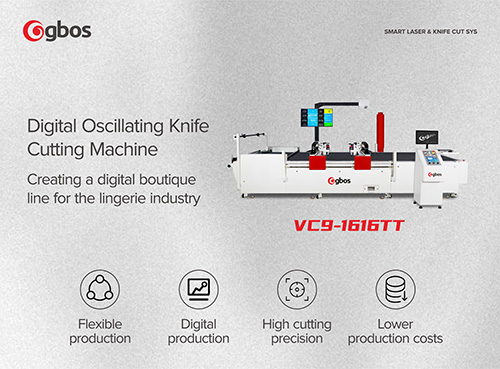

The VC9-1616TT multi-layer digital knife cutting system fits this trend of "small and diverse" orders and helps to implement them from the following perspectives:

- Increased automation: digital cutting equipment eliminates the need for manual intervention, greatly improving productivity and accuracy;

- Improving flexibility: helping to quickly adapt production lines and processes to different order requirements;

- Reducing production costs: digital cutting equipment maximizes material utilization according to order requirements, thereby reducing production costs, waste and inventory;

- Increase production efficiency: digital cutting equipment can cut large quantities in a short time, thus increasing production efficiency and productivity.

- Improve cutting accuracy: Digital cutting equipment can automatically perform pattern matching and cutting to improve cutting accuracy and consistency, and reduce manual errors and scrap rates.

- Enhancing data-based production capacity: digital cutting equipment can record and manage cutting data for each order, thus enabling data-based production and production process optimization;

- Multi-material application capability: not only for Lycra fabric, but also for flexible materials such as nylon and spandex.

In short, the use of digital cutting equipment to enhance the above several manufacturing capabilities can enhance the added value of products for manufacturers, thus improving the brand value and market competitiveness of products and creating a digital boutique line for the lingerie industry!

Professional Digital Cutting Solutions

Smart Layout Planning | Sample Testing | ROI Analysis | Technical Support | Training | Custom Solutions | Parts