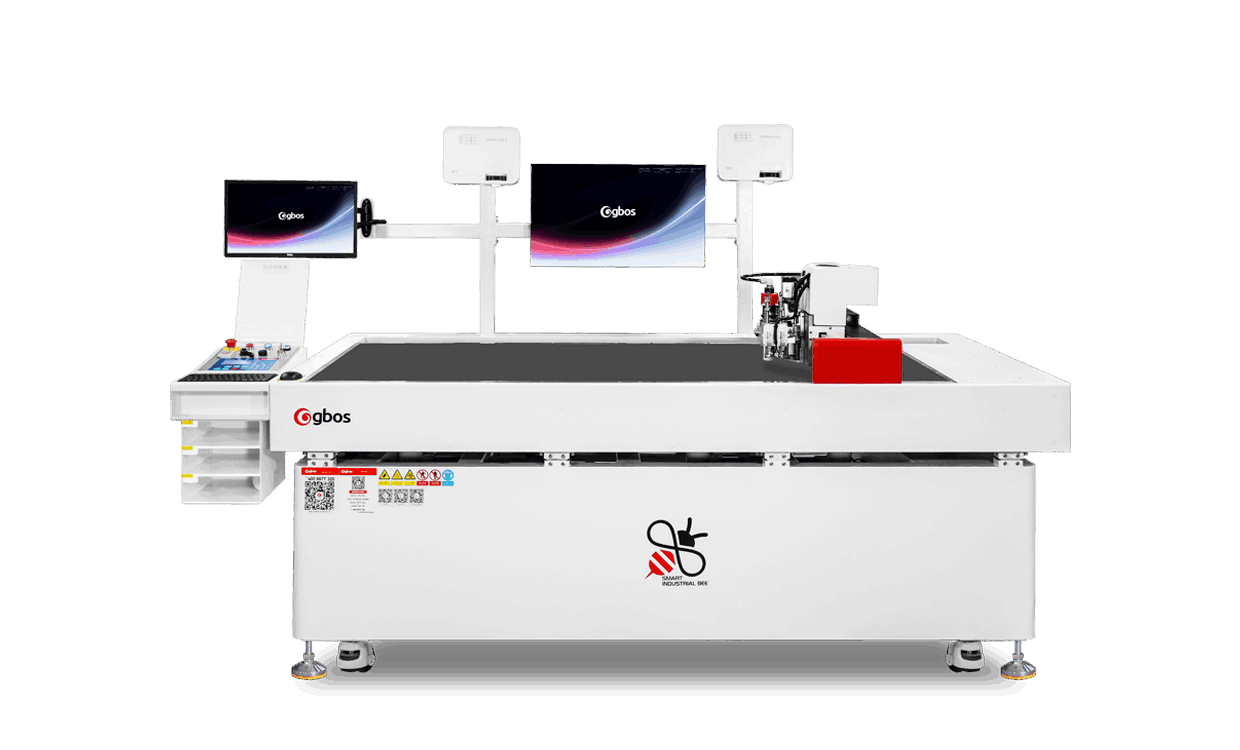

SMALL SMART OSCILLATING KNIFE CUTTING MACHINE

Model: VC9-960

Specification Parameter

Downloads

Smart Industrial Bee Album.pdf

(2.54 MB)

The right cutter for every segment

Perfection in all details

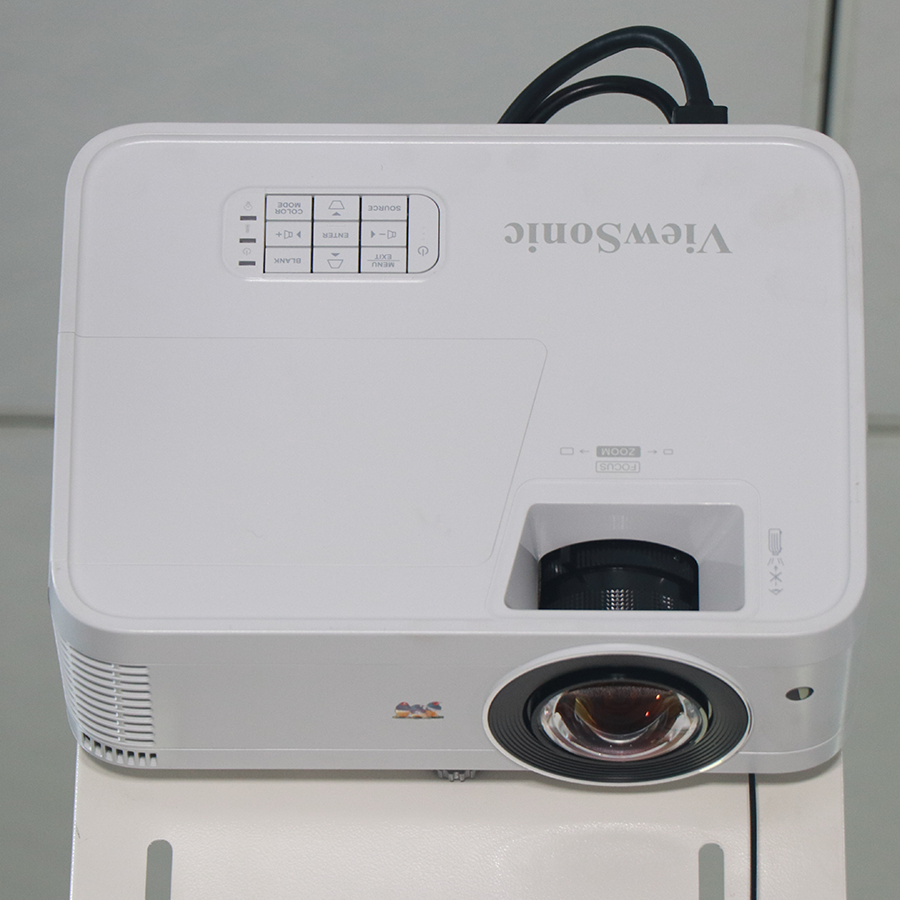

2SCCD AI Visionscan system (Optional)

Dual AI HD industrial camera, highly accurate identification and localization

30 degree inclined design casting platform

The ergonomically designed operating table is flexible to move as you wish, whether it's for receiving or operating materials.

Intelligent nesting system for Irregular materials. (Optional)

This nesting function is more reasonable, easier to operate and more conducive to material saving compared with ordinary array nesting. With offline intelligent nesting system, unlimited length nesting.

Integrated knife holder design

Mute pneumatic cutter head (Electric head optional, for the environment without gas supply) ; intelligent line marking (optional).

Integrated casting frame

Casting and natural weathering 24 months in advance, stable structure, high corrosion resistance, high precision cutting, lifespan of 20 years.

Ergonomics

The operating working table is designed with ergonomic structure with inclined arc for more comfortable operation.

Two cutting areas

Interactive material receiving and cutting on the left and right. Nesting and cutting at the same time.

Movable console

Quickly configure and re-layout according to work requirements for increased efficiency. Reduced blind spots, more ergonomic.

Vacuum adsorption system

Ensure material leveling.

IoT Bridge

Data-based intelligent management, for the use of data to infinitely improve material utilization and reduce production costs.

Intelligent cutting and punching

Cutting,punching,and in one machine.

Modules & Tools

Professional Digital Cutting Solutions

Smart Layout Planning | Sample Testing | ROI Analysis | Technical Support | Training | Custom Solutions | Parts