/sites/default/files/styles/thumbnail/public/2025-02/VC9-1616TT_0.png?itok=m9eVk5Fz

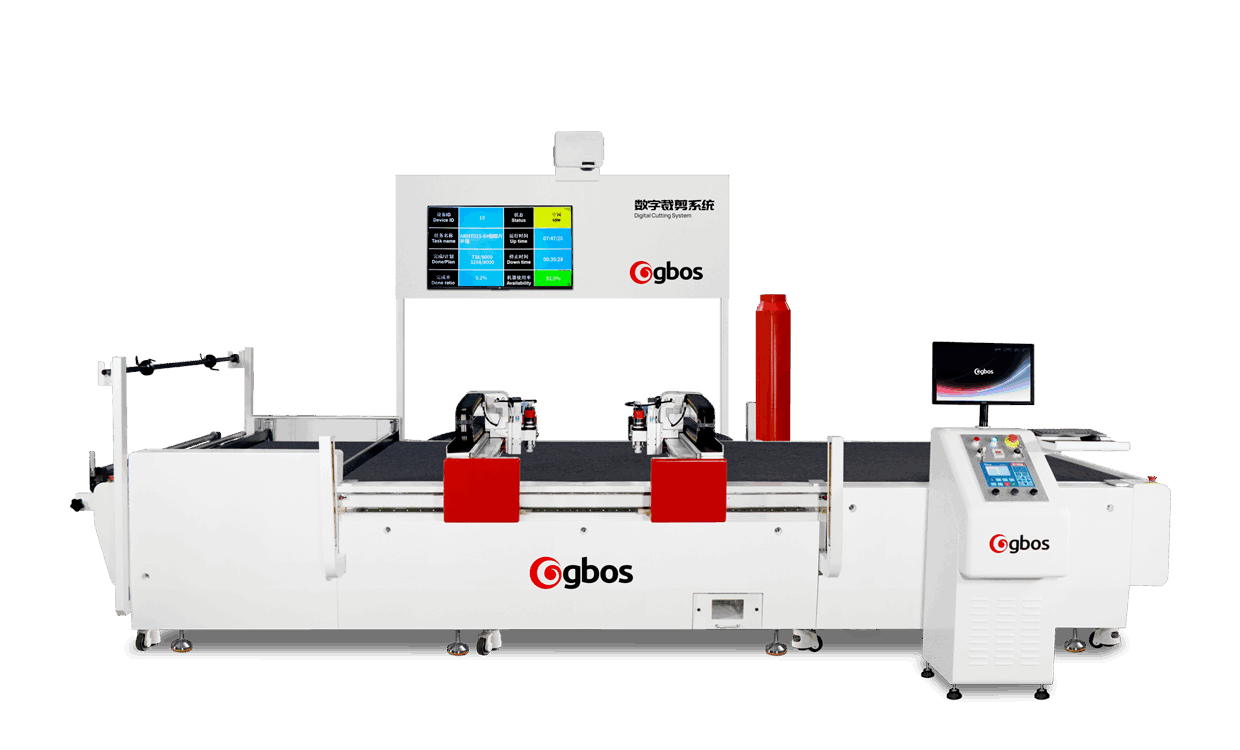

INTELLGENT OSCILLATING KNIFE CUTTING FOR ALL MATERIALS

Model: VC9-1616TT

Specification Paramete

The right cutter for every segment

Perfection in all details

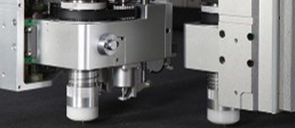

Dual-head asynchronous cutting system

Equipped with an integrated cutter head, it can simultaneously perform cutting and punching. With dual heads operating asynchronously, it effectively increases production capacity.

Projection preview positioning

Clearly project the nesting effect onto the material, allowing real-time viewing of the nesting effect and cutting status.

ITS Regular Material Nesting System

Supports multi-part graphics for intelligent nesting to save material; the same graphic can be arranged in a positive and negative cross-over pattern for extra-long continuous nesting, improving material utilization.

Automatic clamping and feeding system

Automatically clamps and feeds the material to the cutting area and receiving area, effectively improving work efficiency.

Partitioned vacuum system

It can flatten the material and adsorb it to the worktable, improving cutting accuracy and preventing misalignment that leads to inaccuracies.

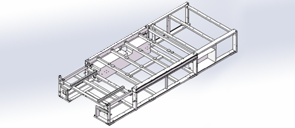

Integrated casting frame

Casting and natural weathering 24 months in advance, stable structure, high corrosion resistance, high precision cutting, lifespan of 20 years.

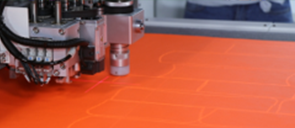

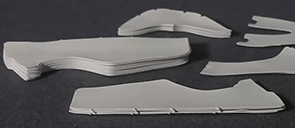

Multi-layer cutting

Multi-layer feeding, and cutting. Suitable for the mid-sole, mesh fabric, soft flexible fabric, PU, TPU, genuine leather, synthetic leather cutting, with unlimited length.

IoT Bridge

Achieve control over the entire smart workshop through digitalization, break down data silos, and improve production efficiency and equipment maintenance.

Modules & Tools

Professional Digital Cutting Solutions

Smart Layout Planning | Sample Testing | ROI Analysis | Technical Support | Training | Custom Solutions | Parts