Let's Take a Peek at Vietnam Footwear Exhibition!

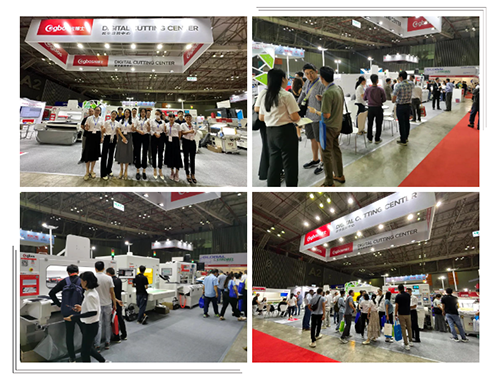

On July 12-14, 2023, Vietnam Saigon Convention & Exhibition Center welcomed the three-day Vietnam International Footwear, Leather & Industrial Equipment Exhibition.

The event attracted the attention of many industry players from all over the world, showcasing the latest footwear technology and innovations.

During the exhibition, GBOS' headquarter and local office in Vietnam jointly exhibited the much-anticipated "Digital Cutting Center" solution for the footwear industry.

Win Unanimous Praise From Users

At the exhibition, GBOS demonstrated a one-stop intelligent cutting + innovative process solution for the footwear industry under the theme of "Digital Cutting Center", which includes various fields such as nesting, cutting, line marking, innovative process applications and IoT.

The one-stop solution meets the digital needs of the entire chain of footwear cutting centers, allowing visitors to more intuitively realize the necessity and great potential of digital transformation. GBOS showed users how to take the "last mile" of transformation and upgrading to achieve 100% digital cutting room.

During the exhibition, GBOS' booth attracted many representatives from famous footwear companies to visit. They praised that the "one-stop intelligent cutting + innovative process" solution can not only improve production efficiency and reduce costs, but also achieve precise cutting and customization needs.

Let's take a peek ☟

5 Kinds of Solutions

- Digital Management, Cost Reduction and Efficiency.

It is understood that in the process of transformation and upgrading of the footwear industry, digital management plays a crucial role.

GBOS keeps pace with the development of the times, continues to work hard on digital cutting and digital management solutions, pours efforts into integrating the IoT platform, interconnects the IT system of the footwear factory and the cutting room, maximizes output, data sharing and minimum manual intervention through digital management, and allows data management to run through the entire production line, which is demonstrated at the exhibition site!

- Ultra-high Leather Nesting Usage Rate, Saving Time and Materials

On July 2-4, ITS series of intelligent leather nesting system appeared in Wenzhou Footwear Exhibition. After 10 days, ITS3 series was shown again at Vietnam Footwear Exhibition.

ITS3 series intelligent leather nesting system, jointly developed by GBOS team and European team, with over 30 years of experience in algorithmic optimization of data, so that the leather nesting is higher utilization rate!

Meanwhile, the application of AI VisionScan technology has also become one of the highlights of the scene, with its contour recognition, positioning point recognition, and automatic recognition of defects, making the leather nesting process more efficient and accurate.

- Diversified Cutting Products, Sparking the Whole Scene

At the footwear show, GBOS exhibited a variety of cutting products, including: gantry type AI VisionScan oscillating knife cutter, oscillating knife cutting machine for all materials, and AI VisionScan double-head asynchronous laser cuttter, which can cope with different process applications, fully demonstrating GBOS' manufacturing strength and mature applications, and verifying the diversity of GBOS products.

- Cartridge Type Line Marking, Efficiency UP, UP, UP!

Based on years of experience in using LA series in customer's site, GBOS R&D team has re-launched the second generation of SP series cartridge-type line marking SP-GH1280AT-SCCD after detailed research.

It adopts the cartridge type line marking, focusing on improving the production speed and maximizing the time consumption for users, and the application of AI VisionScan helps users to achieve higher production precision.

- Innovative Laser Marking and Cutting Solutions, Creativity Unlimited

XXP3 series, 3D dynamic CO2 laser marking cutting machine, which adopts digital optical scanning technology to demonstrate laser leather cutting, engraving, and marking processes on the exhibition site.

In terms of design, it is equipped with AI ▪ CCD VisionScan system to efficiently and quickly complete the pin hole process.

Follow us and let's look forward to more exciting show reports and applications of innovative technologies!

Professional Digital Cutting Solutions

Smart Layout Planning | Sample Testing | ROI Analysis | Technical Support | Training | Custom Solutions | Parts