Advancing Shoe Manufacturing with Die-Less Cutting: Seizing Opportunities Amid the "China+1" Strategy

As global economic integration and the digital revolution drive unprecedented changes, the manufacturing sector is undergoing significant transformation. To swiftly adapt to market shifts and cater to the diverse needs of brands and consumers, manufacturing companies are actively exploring new technologies and solutions. Against this backdrop, Die-Less Cutting technology is emerging as a game-changer, providing companies with unique advantages and enhancing their competitiveness in the "China+1" industrial shift.

The Advantage of Die-Less Cutting

Die-Less Cutting technology breaks the constraints of traditional mold cutting, offering unmatched flexibility and efficiency. With its digital and intelligent capabilities, this technology enables companies to quickly respond to market demands, achieve rapid design iterations, and provide personalized customization. This not only helps meet the evolving preferences of consumers but also allows companies to stand out in a competitive market.

Precision and Consistency in Cutting

Precision and consistency in cutting are critical for introducing automated sewing and assembly processes. Die-Less Cutting ensures high accuracy and uniformity for each piece, providing a reliable foundation for subsequent automated production. This capability significantly enhances the overall efficiency and product quality of shoe manufacturing, giving companies a competitive edge in the global market.

China+1 Strategy

Under the "China+1" strategy, many shoe brands are looking to source production outside of China. The adoption of Die-Less Cutting technology is crucial in boosting the global competitiveness of shoe manufacturers. By digitizing and automating production processes, companies can reduce costs, improve efficiency, and minimize material waste, positioning themselves more favorably in the global market and securing more substantial orders.

Case Studies

Die-Less Cutting technology has gained significant traction in Bangladesh. Several shoe manufacturing companies, including Maf, Edison, Apex, Bay, and Youngone, have adopted this technology with remarkable results. These companies have successfully transitioned to digital production processes, greatly enhancing efficiency and reducing costs after introducing GBOS Die-Less Cutting technology.

For local athletic shoe manufacturers Maf and Edison, implementing GBOS Die-Less Cutting technology was revolutionary. Traditional mold cutting was time-consuming and labor-intensive, limiting product diversity and customization. However, the advent of Die-Less Cutting technology has transformed this scenario.

Maf discovered that with GBOS Die-Less Cutting technology, they could quickly respond to market trends and consumer demands, facilitating rapid product design iterations. Edison found that the technology significantly reduced material waste and increased material utilization, thereby lowering production costs. Youngone enhanced production efficiency and shortened delivery times by reducing manual operations.

These improvements not only boosted Maf, Edison, and Youngone's competitiveness in the local market but also made them more appealing internationally. With Die-Less Cutting technology, these brands can offer a wider range of personalized products to meet global consumer demands.

For leather shoe manufacturer Apex, the introduction of GBOS Die-Less Cutting technology also brought significant changes. In both prototype development and mass production, Apex achieved substantial increases in productivity and cost savings through this technology.

Die-Less Cutting technology allowed Apex to flexibly adjust product designs to meet market and consumer needs. The technology improved material utilization and reduced costs through precise cutting and waste reduction. Additionally, the integration of automated and intelligent equipment reduced manual labor and boosted production efficiency.

These advancements have made Apex more competitive in both the Bangladeshi and global markets. With Die-Less Cutting technology, Apex can offer higher quality, more competitive products, gaining consumer trust and preference.

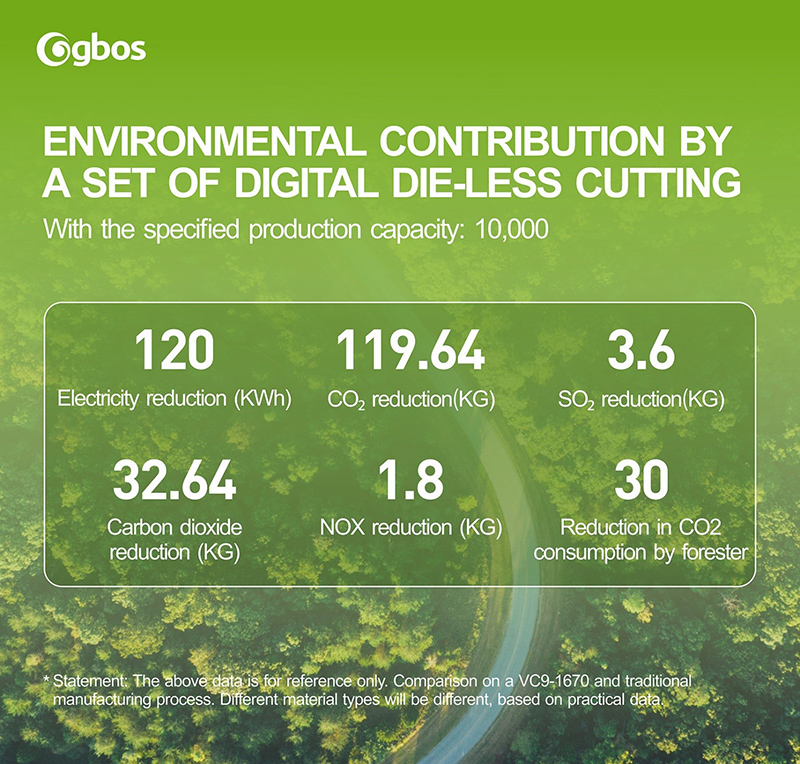

Moreover, Die-Less Cutting technology supports sustainable development. GBOS Die-Less vibrating knife cutting devices are excellent at reducing energy consumption and lowering carbon emissions, contributing to the green and sustainable development of the manufacturing industry.

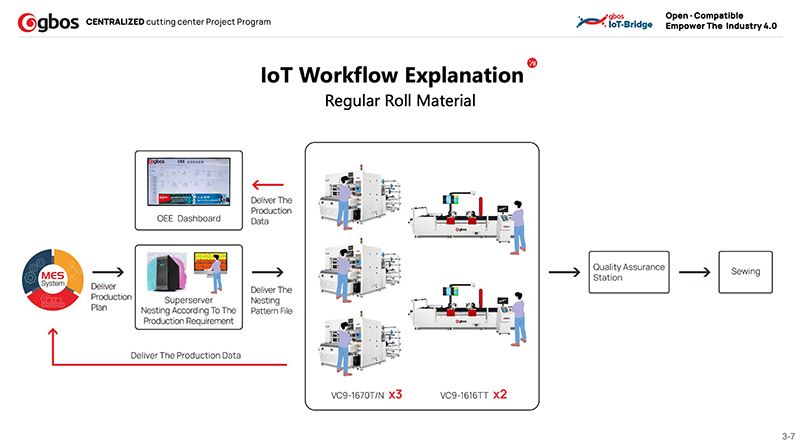

All Die-Less Cutting technologies can seamlessly connect with GBOS's IoT Bridge, enabling real-time monitoring of equipment status, usage details, and overall efficiency. This connectivity provides strong support for decision-making and facilitates continuous optimization and development. The IoT Bridge also allows for data sharing between devices, promoting ongoing improvements.

In the era of digital transformation and Industry 4.0, adopting Die-Less Cutting technology is a clear trend and an effective strategy to enhance core competitiveness in manufacturing.

Professional Digital Cutting Solutions

Smart Layout Planning | Sample Testing | ROI Analysis | Technical Support | Training | Custom Solutions | Parts