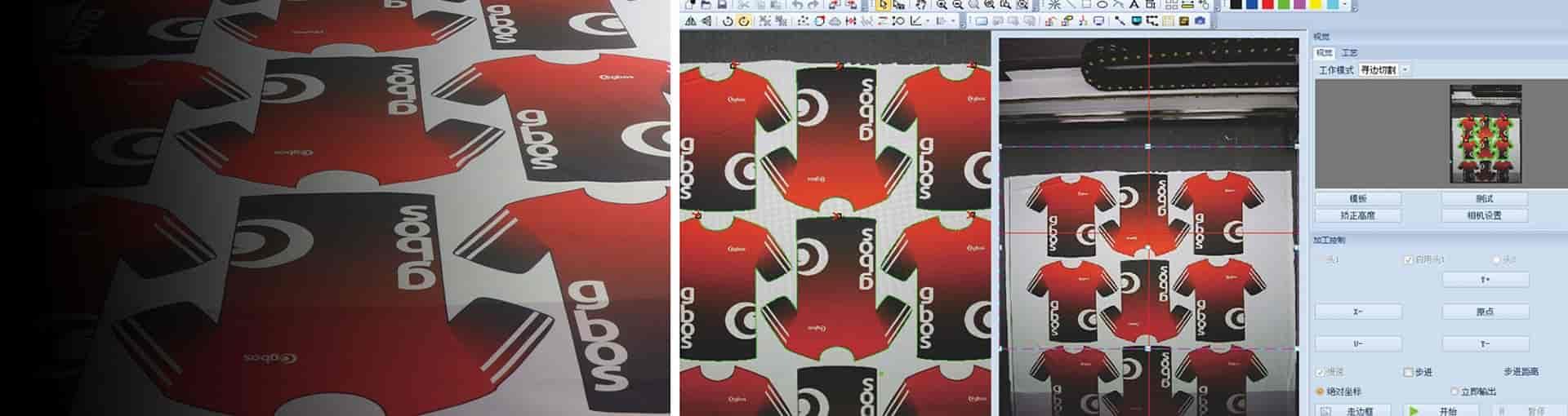

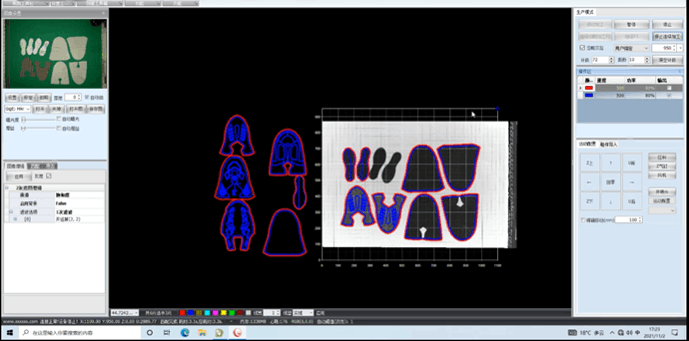

Visual positioning

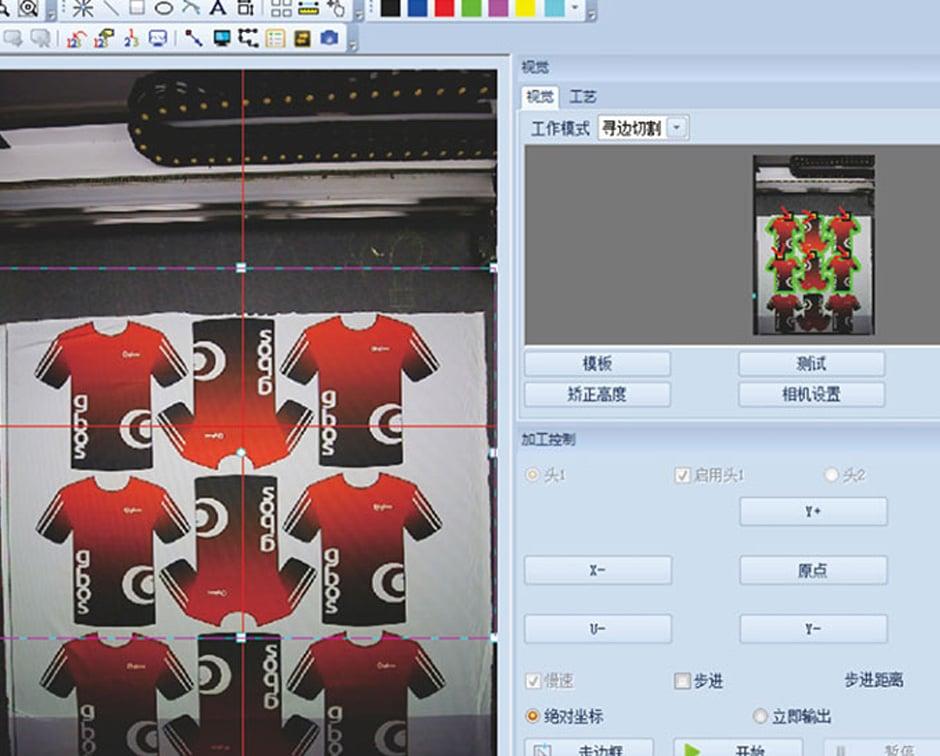

GBOS VisionScan software center

Multipoint locating and cutting; Contour extraction and cutting; Feature point locating and cutting; Intelligent recognition and cutting.

CCD Camera VisionScan function

Super recognition accuracy, error about ±0.2mm

Widely used in garment accessoreis(embroidery patches, woven labels, heat transfer label, leather label, ribbon tapes, digital printing label, etc) and secondary correction process.

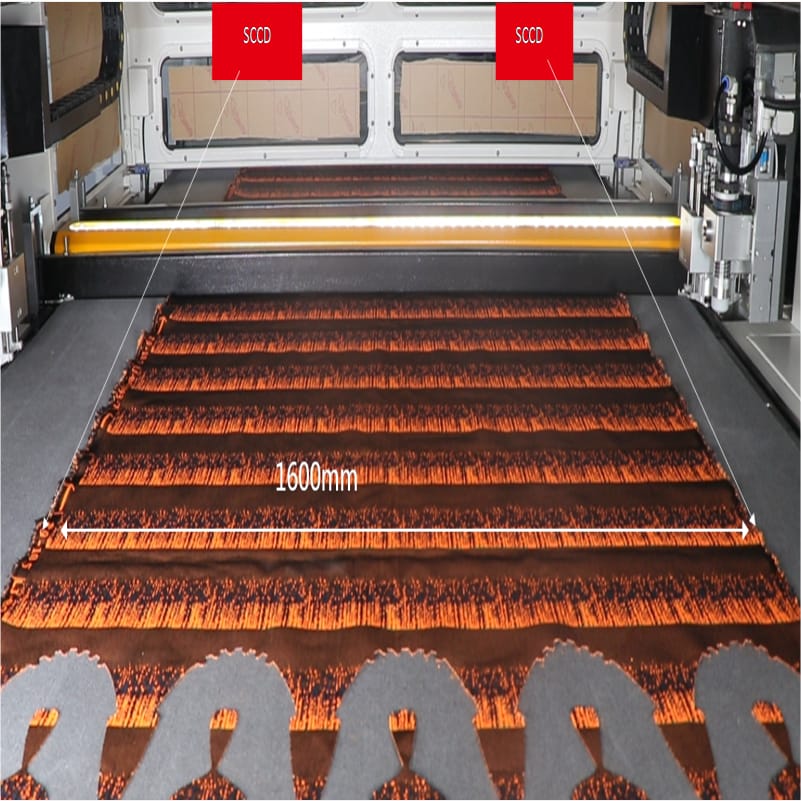

SCCD Super Camera VisionScan Function

Effectively identify area: 850mm*600mm.

Can be equipped with 2 sets of SCCD VisionScan camera.

Widely used in materials with logo or printed patterns.(Such: flags, printing toys, sublimation riding wear/ basketball wear/soccer uniforms/fasion wear/ swimwear, fly knitted shoe upper, mesh shoe upper, etc.)

CCD & SCCD VisionScan System Advantsges

Automatically match pattern according to file, realize simultaneous positioning and cutting of various pattern and any angle.

Automatically locate and identify graphic features and intelligently recognition materials edge to realize edge cutting and large-size material cutting.

According to the color difference of the edge of the graphic, automatically capture and extract the edge cutting line or locate the graphic feature to adjust the cutting contour to achieve cutting along by the edge, which will be avoiding the problem of cutting edge with different size.

Similarity adjustment and intelligent matching of cutting paths according to material deformation.

By setting the product variance rate (adjustable from 0 to 100%), it can automatically identify defective products and reduce manual work processes.

By setting appropriate edge parameters, it is easy to solve the difficult identification of materials of the same color.

It can realize one-time identification of all materials on the working area, and solve the problem of identification and cutting of large size materials.

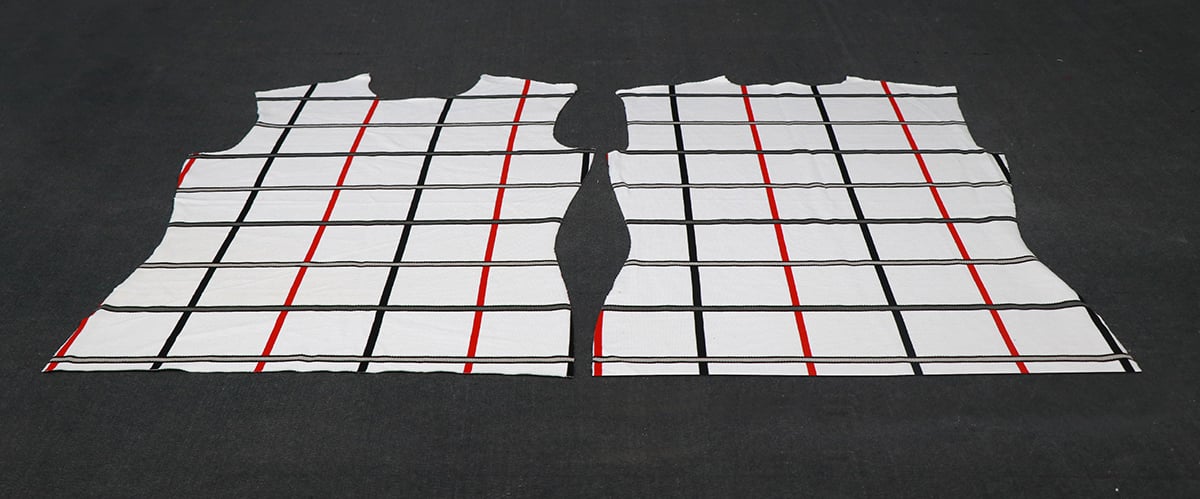

SSCCD, Matching plaids & strips is the camera position function

Stripes matching

Plaids matching

Edge reading

Professional Digital Cutting Solutions

Smart Layout Planning | Sample Testing | ROI Analysis | Technical Support | Training | Custom Solutions | Parts