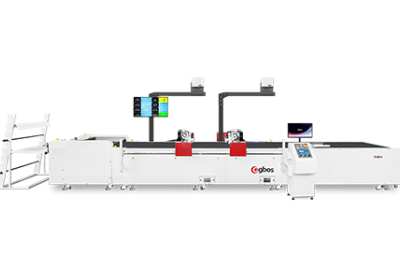

One-stop smart cutting solutions

Leather-ware & handbag

AI vision recognition system accurately identifies various jacquard and patterned materials, working with dual-head asynchronous cutting to efficiently meet production requirements.

Leather shoes

Supports a wide range of leather types—top-grain, split, synthetic, goat leather, and scraps—for material-saving nesting and cutting.

Vehicle upholstery

Features an extra-large cutting area to precisely handle large automotive interior panels; combined with the ITS3 intelligent material-saving nesting system, it maximizes leather utilization for highly efficient production.

Expand More+

Videos Show

Expand More+

Solutions Resources

Jul 1,2025

Discover all our Live or Replay events and refine your search by selecting a filter and criteria.

Mar 16,2024

Data intelligence enhances interoperability, reduces environmental impact, and precisely positions each tailored leather piece, enhancing seating comfort. Transitioning from small batch production to large batch orders while complying with Industry 4.0 standards, GBOS elevates cutting quality through intelligent [one-stop] nesting + cutting.

Jul 31,2025

Discover all our Live or Replay events and refine your search by selecting a filter and criteria.

Expand More+

Customer Voice

Book an virtual demonstration with us to learn more about digital cutting and process solutions.

Gallery image

Professional Digital Cutting Solutions

Smart Layout Planning | Sample Testing | ROI Analysis | Technical Support | Training | Custom Solutions | Parts