The Digital Wave! Are you ready to take?

On August 17, 2022, a Notice on Supporting the Pilot Work of Digital Transformation of Small and Medium-sized Enterprises was jointly issued by the Ministry of Industry and Information Technology (MIIT) and the Ministry of Finance (MOF). Among them, to create a number of "small, fast, light and accurate" digital system solutions and create 4000-6000 "small lighthouse" enterprises as a digital transformation benchmark enterprises, is an important guiding direction for the manufacturing industry as pointed out in the notice. Among them, textile, clothing and leather products processing for the transformation of one of the pilot industry segments.

The future development trend of the manufacturing industry: small, fast, light and accurate

Manufacturing development is the cornerstone of the development of the real economy, the small size of the manufacturing industry, fast, lightweight, accurate development is the top priority of the development of the digital economy, the digital economy and the real economy in-depth integration of the development is to achieve high-quality development of favorable choices. However, the traditional manufacturing model of manufacturing digital development has brought many challenges to the textile, apparel and leather industry processing, for example: high labor costs, process time-consuming, energy consumption and other issues are endless.

In order to actively respond to national policies, as well as practical solutions to the pain points of the traditional manufacturing industry, GBOS has been committed to the research and development of intelligent cutting equipment and technological innovation, through the research and development of laser machines, oscillating knife cutting equipment, other automation equipment and IoT Bridge as the core. As well as equipped with intelligent visual recognition, projection preview positioning and other 30+ optional module systems, to create a one-stop digital core technology-driven intelligent cutting equipment & innovative process solutions, empowering digital intelligent manufacturing!

Two major technologies to empower the textile, apparel and leather industries, empowering digital intelligent manufacturing

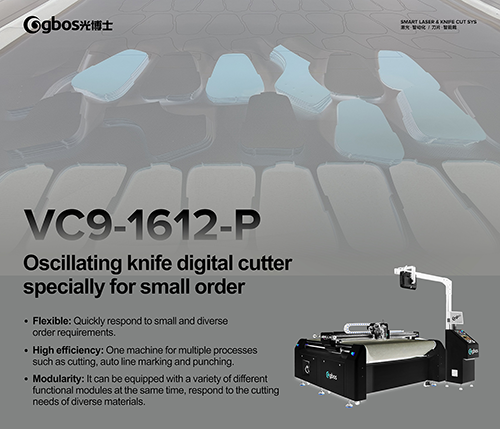

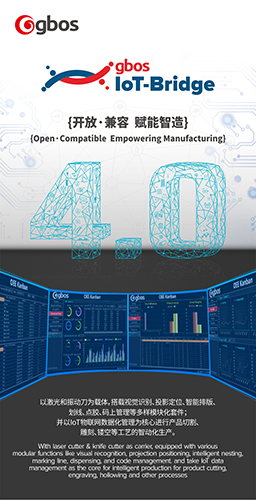

In the textile, garment and leather industries, the VC9-1612-P and the IoT Bridge have been developed to empower digitalized smart manufacturing.

VC9-1612-P is an oscillating knife cutting machine for small orders, integrating cutting, line marking and punching, which is made for reducing the process flow and responding quickly to small and diversified orders.

IoT Bridge can run through the entire production line, enabling the oscillating knife cutting machine, laser machine, line marking machine, arm spraying machine and other equipment to be integrated into the IoT unified management, so as to achieve real-time view of the equipment status, and help enterprises to replace empirical judgments with digital drive, optimize output with digital management and empower the future of digital manufacturing.

We hope that through the "small, fast and precise" digital cutting solution, we can help enterprises flexibly respond to customer needs. Through the digital management system, the management can make decisions through data, for the enterprise to reduce costs and increase efficiency.

Professional Digital Cutting Solutions

Smart Layout Planning | Sample Testing | ROI Analysis | Technical Support | Training | Custom Solutions | Parts