GBOS Was Chosen As One of the "SRDI" Cultivation List at the Municipal Level

Recently, the Dongguan Municipal Bureau of Industry and Information Technology released the list of the first batch of Dongguan "Specialization, refinement, differential and innovation " enterprise cultivation base. GBOS has achieved outstanding results in technological innovation, digital tailoring solutions, and high-quality development. After a series of enterprise recruitment and strict approval processes, he has been recognized by national authoritative departments and has successfully entered the cultivation stage.

"Specialization, refinement, differential and innovation" refers to the Megaproject implemented by the state to guide enterprises to take the path of specialization, refinement, characteristics and innovation, and enhance their independent innovation ability and core competitiveness.

01 Specialization

Since its establishment in 2005, GBOS has always adhered to a professional development path and has been committed to the research and development of laser equipment, oscillating knife cutting machines, and other automation products, providing professional one-stop intelligent cutting solutions for flexible materials.

So far, we have provided over 2000 application solutions to over 30000 global users. Every meticulously crafted solution witnesses GBOS's technological and process innovation, and in this beautifully carved of innovation, it has won 104 patent certificates.

02 Refinement

We attach great importance to the refinement of research and development and manufacturing, the specialization of product services, and the innovation of business management, and take action accordingly.

R&D and manufacturing excellence: Every product launched on the market must be our lean carving of craftsmanship and tools. We adhere to the concept of empowering China's intelligent manufacturing, so that every user who owns our products can make a leap in quality and quantity.

Product service specialization: The delivery center has a production area of 40000 square meters, and after-sales service centers and offices are located worldwide (Guangdong, Central China, Kunshan, Jinjiang, Vietnam, Bangladesh, Indonesia, etc.)

·Multiple high-precision visionscan systems: CCD, SCCD, SSCCD, etc., with recognition accuracy up to ± 0.01mm;

·S-Denim 6.0 system developed specifically for the denim washing industry;

·3D 5-axis CO2 laser application technology to solve high-precision cutting of irregular product surfaces;

·Free from mold digital cutting technology, reducing operating costs and increasing production capacity;

·OEE data dashboard, breaking data silos, achieving digital management, and achieving cost reduction and efficiency increase;

·Open and compatible IoT Bridge empowers Lean Manufacturing 4.0.

New type of business management: The company implements comprehensive quality management, establishes a quality management manual, and organizes the preparation of "Technical Key Points for Positions" and "Component Inspection Standards". In order to standardize operations and operational management, more than 190 standard specification documents have also been formed.

03 Differential

The company has established an independent R&D department for refined and intelligent product research and development, with over 30 R&D personnel. Each engineer has solid experience in intelligent laser and oscillating knife equipment. We can provide customized services for different types of products according to the different needs of users.

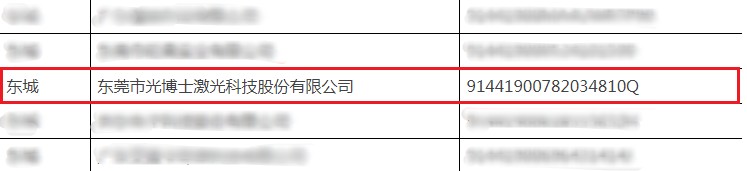

At the same time, we are also the main supplier and strategic partner of some well-known domestic brands. We actively carry out the transformation of scientific and technological achievements, and have now obtained more than 104 patents and 30+functional modules. At the same time, we have passed various certifications related to mid to high-end intelligent equipment, such as ISO9001:2005, SGS CE certification, TUV CE certification, FDA certification, intellectual property management system, etc.

04 Innovation

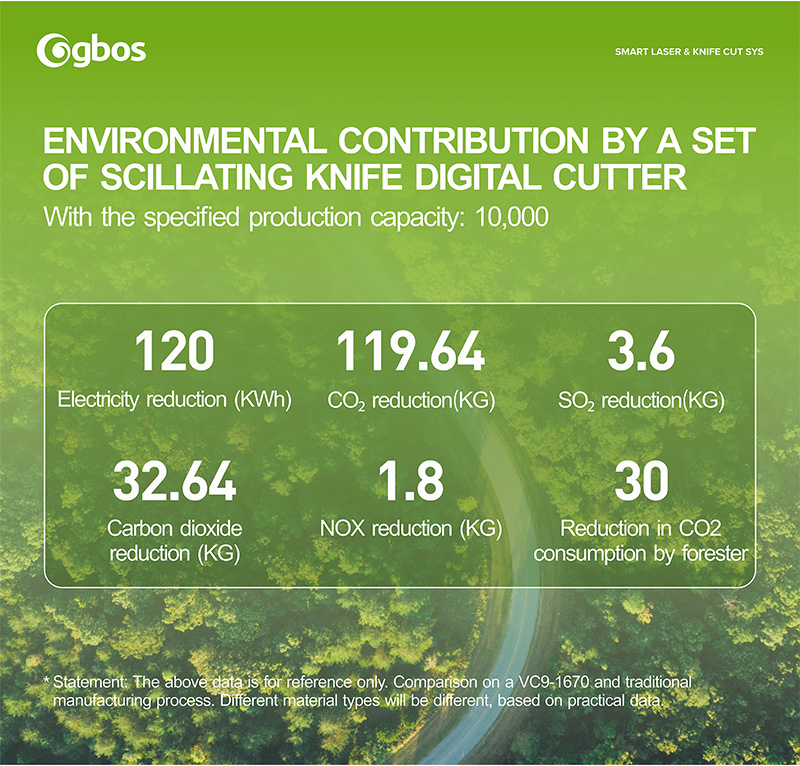

Under the concepts of "carbon neutrality," "sustainable development," and "green environmental protection," we continuously innovate intelligent manufacturing and empower sustainable development through forward-looking technologies such as digital cutting solutions, S-Denim 6.0 systems, IoT Bridge, and the integration of green environmental protection concepts into production and daily life.

We are committed to creating sustainable operating modes for advanced digital production. By using laser technology and S-Denim 6.0 technology, we pay tribute to traditional processes with digital technology, eliminate processes that are harmful to human health, and achieve sustainable green intelligent manufacturing, bringing more ecological benefits to enterprises.

In the era of the Internet of Things, we use the IoT platform to build a carbon emission digital platform for the intelligent manufacturing industry chain. With the help of digitalization and Internet of Things technology, we help enterprises monitor and manage energy consumption and emissions, and digital production, empowering industrial energy conservation and emission reduction, and assisting in carbon neutrality.

Under the concept of green environmental protection, we incorporate new development concepts into practice, deploy new energy, focus on reducing carbon emissions throughout the factory, create a "0" carbon factory, and jointly build a "0" carbon future.

The selection of the "specialized, refined, and innovative" cultivation database this time is another recognition of the comprehensive development strength of GBOS by government units. We will continue to strengthen our research and innovation efforts in digital cutting solutions, and strive to become a trustworthy enterprise for users, building a one-stop intelligent cutting solution for future and sustainable development.

Professional Digital Cutting Solutions

Smart Layout Planning | Sample Testing | ROI Analysis | Technical Support | Training | Custom Solutions | Parts