What Is an Oscillating Knife?

With the continuous development of manufacturing industry, cutting technology is also evolving. As an innovative cutting tool, oscillating knife subverts the previous production mode of knife die cutting, and its innovative move of die less cutting brings more possibilities for manufacturing industry, which is popular among manufacturers of various industries.

So, what is an oscillating knife? What is the difference between oscillating knives and traditional die cuts? And what are the advantages of GBOS digital oscillating knives? In the following, the above questions will be introduced in succession.

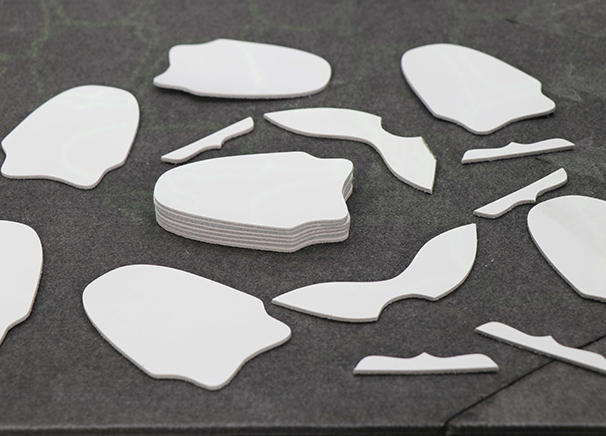

Oscillating knife is a high-speed oscillating cutting tool. Through high-frequency oscillation, the knife edge oscillates back and forth on the surface of the material, resulting in tiny cutting strokes to achieve fast and efficient cutting results. Compared with traditional die cutting, the digital Oscillating knife gets rid of the limitations of dies and molds, realizing die-less cutting and achieving cost reduction, efficiency and accurate production results.

Focusing on intelligent cutting for 18 years, GBOS focuses on customer needs and market dynamics, focuses on data and intelligence, and independently researches and develops digital intelligent cutting equipments to create a better using experience for customers from the following 5 aspects:

1. Die-less

With the adoption of die-less technology for GBOS digital Oscillating knives, we no longer rely on complex die designs. All for optimizing your production:

- 0 Die production costs

- Reduction of storage costs

- Reduction of overhead costs

- Reduction in manufacturing costs

- Time saving

- Simplification of operation process

- Quality Improvement

2. Various types of orders supported

In the face of diversified market demands, GBOS can meet the needs of small & diversified orders and large orders at the same time.

- Small quantity & diversified orders

Flexibility, speed and small quantity have become the most concerned points for manufacturers. GBOS empowers enterprises to respond to various types of orders efficiently and quickly by launching 1+N modular application solutions.

- High-volume orders

Meanwhile, GBOS oscillating knives can provide intelligent solutions for the production of large-volume orders, which can enhance the cutting efficiency and ensure its quality at the same time, so as to achieve a win-win situation in terms of speed and precision, and improve your production efficiency.

3. High quality cutting

Compared with the traditional knife die, the Oscillating cutting greatly reduces the error, and the cutting effect is flat without burrs, which improves the cutting precision and ensures the quality of cutting.

4. Digitalization

We manage the optimization system through digitalization. We monitor the operational efficiency of production through the OEE Dashboard. By analyzing the various aspects of the OEE , you can get a clear picture of how efficient your equipment is, how much is being lost in which part of production, and what improvement work is being done. With long-term use of OEE, companies can visualize and manage the production process, easily find the bottlenecks affecting production efficiency, and thus improve the transparency and efficiency of production.

5. Extensive applicability

GBOS's diversified knives and flexibility enable it to cope with cutting of different types of materials, and it has a very wide range of applications in many fields such as shoes, luggage, garment, advertising and packaging, and automobile interiors, etc.

Overall, as an innovative cutting tool, oscillating knife is driving cutting technology forward with its high efficiency, precision and digitalization. It has become the industry's preference to choose die-less and digital oscillating cutting, so let's meet this digital trend and embrace the future!

Professional Digital Cutting Solutions

Smart Layout Planning | Sample Testing | ROI Analysis | Technical Support | Training | Custom Solutions | Parts