DUAL-HEAD ASYNCHRONOUS OSCILLATING KNIFE CUTTER

Model: KC1625TT-RT-2P-FOAM

Specification Parameter

Perfection in all details

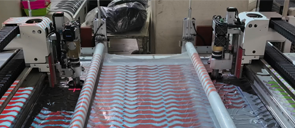

Dual-head asynchronous cutting system

Dual-head interactive cutting, doubling the efficiency.Linear guide system for precise control of movement, reducing errors.

Servo knife head and punching device (optional)

GBOS servo cutting head is mainly used for cutting multiple layers of thick materials. An integrated knife holder can be equipped with a punching device to complete punching needs simultaneously after cutting.

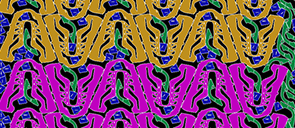

Projection preview positioning system

Instant preview of nesting effects — convenient, fast.

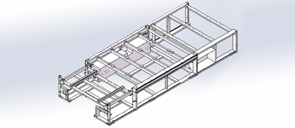

Integrated machine frame

The body is cast in one piece, making it deformation-resistant even under frequent use. It is designed to last for 20 years.

Intelligent nesting system

Equipped with a smart material-saving nesting system, capable of automatic nesting for unlimited lengths, improving material utilization.

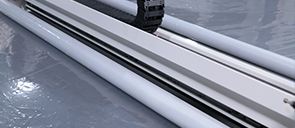

Automatic lamination device

High-precision lamination: Achieves consistent coverage and meets high-quality standards by precisely controlling the thickness and uniformity of the film layer.Automated operation: Reduces manual intervention, increases production efficiency, and lowers operating costs by implementing automated processes.

Automatic clamping and feeding device

The GBOS automatic clamping and feeding device is designed to improve the efficiency and precision of the material handling process. It automatically clamps and feeds materials into the cutting system, reducing manual intervention and minimizing the risk of errors. This device ensures consistent and accurate material placement, enhancing the overall production speed and quality.

Zoned vacuum adsorption system

Ensure material leveling.

IoT dashboard

Real-time data display, remote monitoring, data analysis and reporting, equipment management, visual operation interface.

Modules & Tools

Comprehensive Customer Support

Service contract; Remote service; Customer service center; Training; Hardware upgrade; Component stock; Special task support; Upgrade/moving/renew; Service at production facility; Sample innovation & development;