KC1625 makes a big difference -- the successful transition of XuTai as an example

In 2019, Dongguan XuTai Sports Bag Manufactures Co., LTD (hereinafter referred to as XuTai), a subsidiary of Nam Liong Group, ordered GBOS initial generation open oscillating knife cutting machine KC1625, which has given a strong impetus to improve production efficiency and product quality.

KC1625 is a flexible material cutting system designed to provide digital intelligent cutting solutions for manufacturers of flexible materials with large cut pieces. So far, this machine has been used in XuTai cutting room for 4 years! What surprises has it brought to the company during the 4 years of use?

01 About XuTai

Dongguan XuTai Sports Bag Manufactures Co.,LTD is a wholly-owned subsidiary of Nam Liong Group, specializing in the production of fashionable functional bags, handbags, trolley cases, computer bags and other products. With a wide range of products, it is exported all over the world and has cooperated with HM, Armani, Thule and other brands.

02 User's Voice

In recent years, the luggage industry is developing rapidly and the manufacturers are in the stage of transformation and upgrading. As a company with advanced professional technology and rich manufacturing experience, XuTai understands the disadvantages of traditional production in terms of time consuming, difficult and labor-intensive in making die molds.

In the process of receiving orders, they deeply appreciate the necessity of digital transformation; after evaluation, XuTai chose to introduce GBOS KC1625 digital cutting system to realize digital precision cutting in luggage industry and use it with laser machine to complete some small batch type orders, reduce the cost of making die molds and improve the labor intensity of employees!

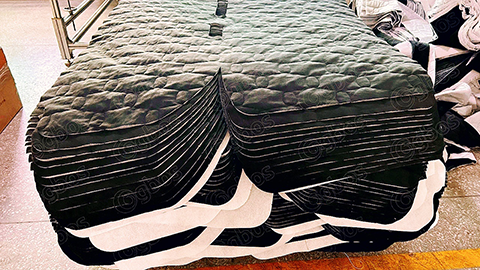

The introduction of KC1625 is part of XuTai's continuous pursuit of innovation and improvement, with a capacity of 3500pcs/8h per oscillating knife cutter.

According to user's feedback, during the 4 years of using the oscillating knife cutting machine, its excellent capacity efficiency has met the production efficiency requirements, and the stable operation of the equipment has also enhanced their confidence and strength to take more orders.

GBOS KC1625 is an open multi-layer flexible fabric cutting system designed for large area cutting, offering modular features such as visual recognition system, projection preview positioning, etc. for multiple applications and optimal return on investment. Its use of one-piece molding process enables a machine life of 20 years and more, and its unique design enables higher cutting accuracy and more stable machine performance, providing strong support for major manufacturers to unleash their growth potential!

The successful transformation of XuTai demonstrates the potential and future possibilities of the digital era. In this era of challenges and opportunities, let's work together to create a stronger "digital cutting center"!

Professional Digital Cutting Solutions

Smart Layout Planning | Sample Testing | ROI Analysis | Technical Support | Training | Custom Solutions | Parts