/sites/default/files/styles/thumbnail/public/2023-09/KC1625TT-SD%20Oscillating%20knife%20digital%20cutter_0.png?itok=wwQnmhXx

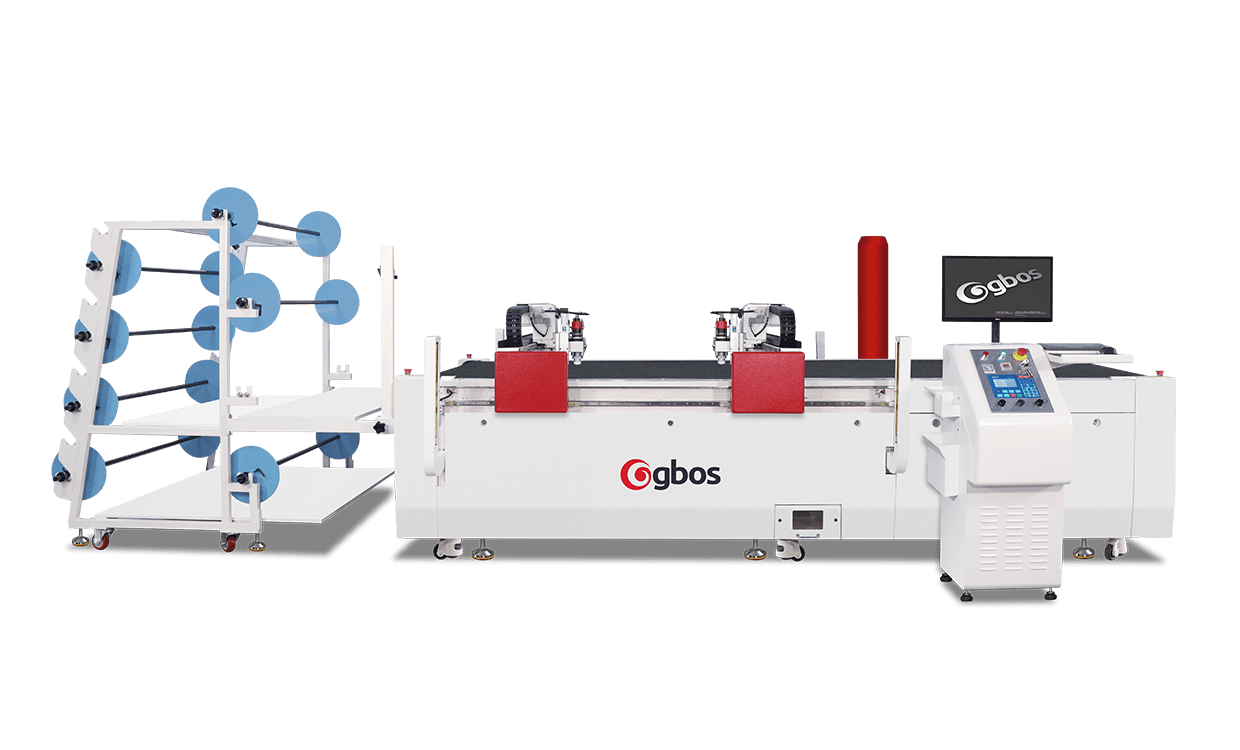

DUAL-HEAD ASYNCHRONOUS OSCILLATING KNIFE CUTTER

Model: KC1625TT-AT-SD

Specification Parameter

The right cutter for every segment

Perfection in all details

Dual-head async system

Dual-head asynchronous cutting, with an integrated knife holder design that combines cutting and punching. Optional configurations include single-head dual punch or 4-punch.

Intelligent nesting system

The intelligent nesting system for regular materials features automatic counting and nesting; it can intelligently nest multi-part graphics to save material. It supports ultra-long continuous nesting of the same graphic in both positive and negative crossover patterns, thereby improving material utilization.

Projection preview positioning

Clearly project the nesting effect onto the material, allowing real-time viewing of the nesting effect and cutting status.

Integrated knife holder design

Integrated cutting and punching device, the punching device can choose single punch or double punch.

Red light positioning

Infrared positioning is used to ensure that the material remains within the normal working area and does not cross the boundaries.

Partitioned vacuum adsorption

Through zoned suction, it ensures the flatness of the material and reduces the likelihood of misalignment.

8-layer auto feeding rack

No manual material laying is required, and up to 8 rolls of material can be placed at once, improving the machine's operational efficiency.

IoT Bridge

Achieve control over the entire smart workshop through digitalization, break down data silos, and improve production efficiency and equipment maintenance.

Modules & Tools

Professional Digital Cutting Solutions

Smart Layout Planning | Sample Testing | ROI Analysis | Technical Support | Training | Custom Solutions | Parts