Digital "green" cutting, using every inch of available leather.

In August, 2022, a report shows that the number of Chinese Leather Upper Leather Shoes Manufacturing Enterprises in 2021 is 2,122 from 2020-2021 Leather Shoes Industry Operation.

It can be said that in the past 30 years, with the deepening process of globalization, China has become a veritable leather production power in the world. At the same time, sports and leisure shoes in the integration of leather materials is a major trend, the relevant policy documents issued also led the footwear enterprises to embark on the road of technological development.

But in the process of rapid development of the industry, in this consumer-oriented stage, the major leather shoes manufacturers are facing more and more competitive pressure and many aspects of the stringent requirements.

01

From the perspective of manufacturing

Standing in the manufacturing point of view, the manufacturing industry urgently needs to solve the frequent "labor shortage" problem, and to cope with the continued high cost of raw materials, fully consider how to improve the utilization of materials, to achieve cost reduction and efficiency.

From the perspective of brands

From the brand's point of view, under the general trend of brands insisting on innovation and catering to consumers with diversified and personalized products, manufacturers should not only actively adjust their thinking to adapt to small-volume orders with a wide range of categories and uneven order sizes, but also make use of innovative technology to release production capacity, cope with large-volume orders with short delivery periods, and have the ability to innovate.

From the perspective of enterprise management

From the perspective of enterprise management, how to build a digital workshop, introduce lean management, achieve precise planning, lean production, visualization, fine management at the workshop level, and so on, are all challenges that manufacturers need to face to effectively enhance competitiveness.

02

Digital transformation is imminent

All of the above challenges and requirements for manufacturers, none of which are clarifying the implementation of the leather footwear industry to build a digital production plant to enhance the core competitiveness of the enterprise's urgency and necessity. Let's find out why more and more footwear industry choose GBOS' one-stop intelligent nesting+cutting solution.

03

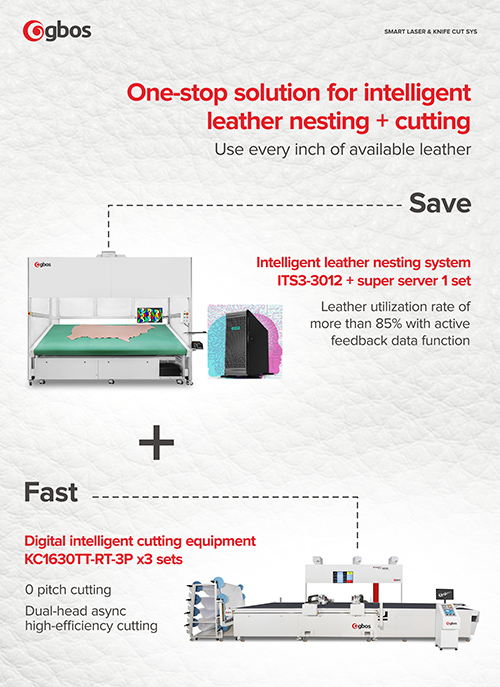

Using every inch of available leather

GBOS' digital leather nesting + cutting solution has been fully verified in the footwear industry market, and when it changes the traditional manufacturing model, it achieves the deep integration of intelligent production and digital management, helping to create a mold-free, labor-saving, time-saving and labor-saving leather production model.

The specific performance is as follows:

- Using up every inch of available leather: after using ITS3 intelligent nesting equipment, leather nesting time is reduced to about 3 minutes / sheet, leather nesting utilization rate of up to about 85% and above; leather cutting in the realization of 0 pitch cutting at the same time, cutting efficiency of about 8 pieces of leather / hour; (data for reference only, the actual data according to the complexity of the cut piece)

- Extremely flexible cutting program: with the help of projection preview positioning system, vacuum adsorption system, multi-layer feeding system and other functions, it can not only complete the efficient and accurate cutting of leather, but also complete the multi-layer and efficient production of synthetic leather, such as PU, TPU;

- Data visualization management to make your smart workshop stand out: production efficiency improvement largely needs real-time and accurate data support. GBOS IoT Bridge as well as OEE Kanban not only help to reduce paper-based production, but also greatly help in assisting management decisions.

If your company is exploring how to build a digital production workshop in the leather industry, GBOS' one-stop intelligent nesting + cutting solution is the right choice to help your company improve competitiveness.

In the future, GBOS will continue to "digital" as the guide, to help enterprises "use up every inch of available leather" as the inner driving force, continue to plough the leather industry technological innovation, industrial transformation and product upgrading of the integration of the development of intelligent production lines, digital management workshop and other changes. Digital management workshop and other changes.

Professional Digital Cutting Solutions

Smart Layout Planning | Sample Testing | ROI Analysis | Technical Support | Training | Custom Solutions | Parts