About 315 results

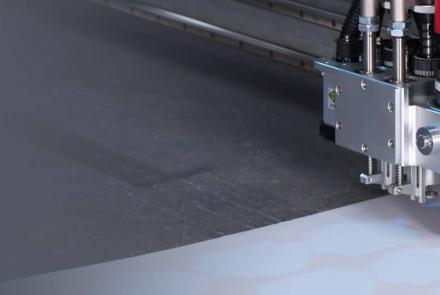

Leather cutting knife, for synthetic leather, simple patterns.

For cutting flat-knitted fabric.

For cutting mesh fabric, simple patterns, fast speed.

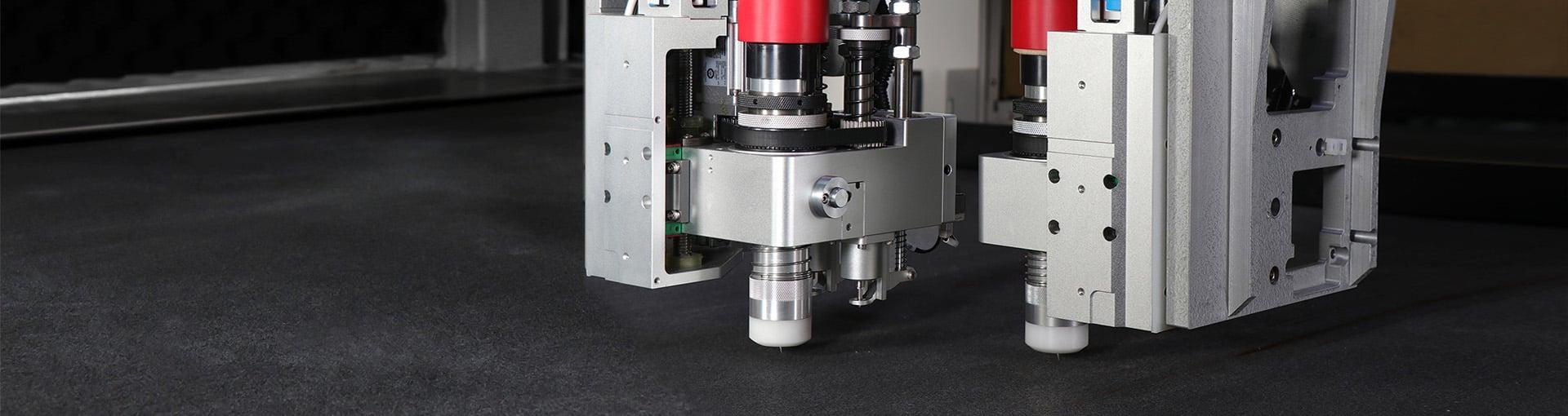

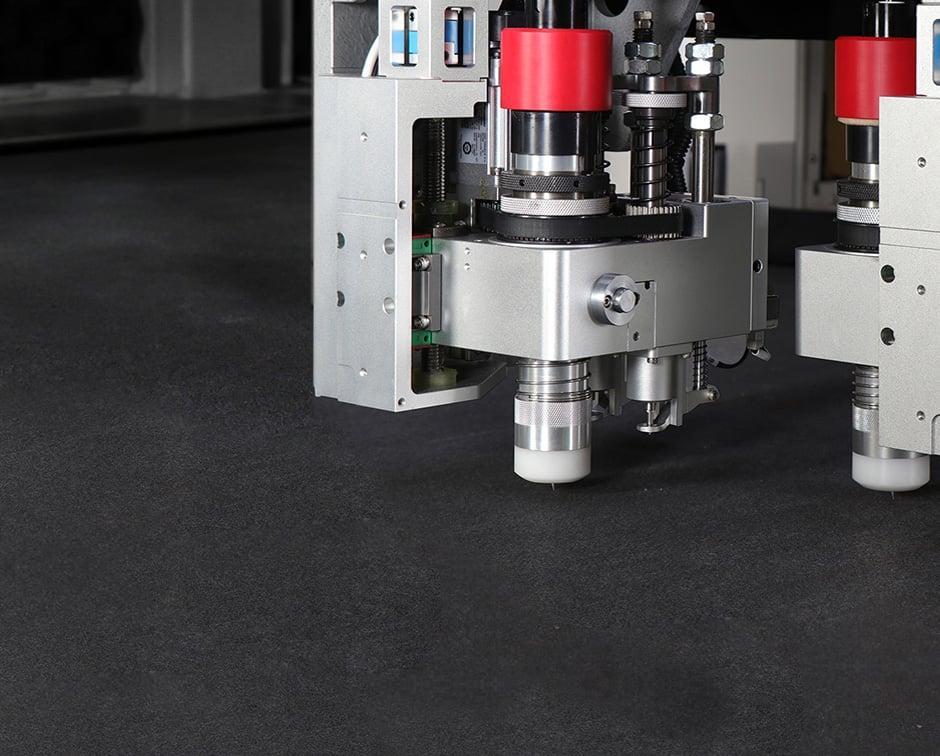

Strive for craftsmanship smart manufacture and producing, adopt to double-head async and vacuum adsorption systems, high speed precision cutting technology. Innovative technology and digital cutter help our customers to realise their individual requirements in production.

Especially configured digital cutter system for foam cutting, ensure the material without deformed, enhance cutting quality, and is well adapted to a wide range of creative shapes for cutting.

Toe puff is a key shoe-making material—how to cut it for high-tech demands? The GBOS digital knife cutting machine tailors toe puff tablets to each shoe’s style. Automation is the future of shoe materials.

Rubber widely used in footwear, automotive industry. Easily operation, die-less cutting, importing data for direct cutting by using auto digital cutter.

100% Zero die-cutting digital solution, mature and complete, achieving the optimal solution for all materials in one stop

AI VisionScan System & Intelligent Nesting Solution enable efficient multi-layer cutting and punching of genuine leather, synthetic leather, and regular roll-to-roll materials.

As underwear manufacturing evolves and comfort demands rise, traditional cutting falls short—personalized digital cutting is the solution.

Professional Digital Cutting Solutions

Smart Layout Planning | Sample Testing | ROI Analysis | Technical Support | Training | Custom Solutions | Parts